In the food and beverage manufacturing industry, maintaining excellent hygiene is of utmost importance. High-level cleaning, which targets hard-to-reach areas above 2.5 meters, plays a crucial role in this effort. Advanced Cleaning Services (ACS) is one of the leading suppliers when it comes to high-level cleaning, leveraging specialized processes and technology to ensure the highest standards of cleanliness and food safety.

What is High-Level Cleaning?

High-level cleaning involves the thorough cleaning of all surfaces above the standard reach of typical cleaning routines. These areas, often overlooked, can harbour dust, pests, and other contaminants that pose significant risks to food safety. Effective high-level cleaning is essential for preventing contamination and ensuring a hygienic production environment.

The Importance of High-Level Cleaning in Food Manufacturing

In food and beverage manufacturing, contamination can occur from various sources. While visible surfaces are regularly cleaned, the areas above 2.5 meters are frequently neglected. Dust accumulation, pest infestations, and microbial growth in these high areas can lead to serious food safety hazards. High-level cleaning mitigates these risks by ensuring that all areas, including ceilings, overhead pipes, and ducts, are kept clean and free from contaminants.

Advanced Cleaning Services’ Approach to High-Level Cleaning

ACS has developed a comprehensive approach to high-level cleaning, ensuring that every inch of a facility is maintained to the highest standards. Our methodology includes the following key components:

1. Specialized Equipment and Techniques

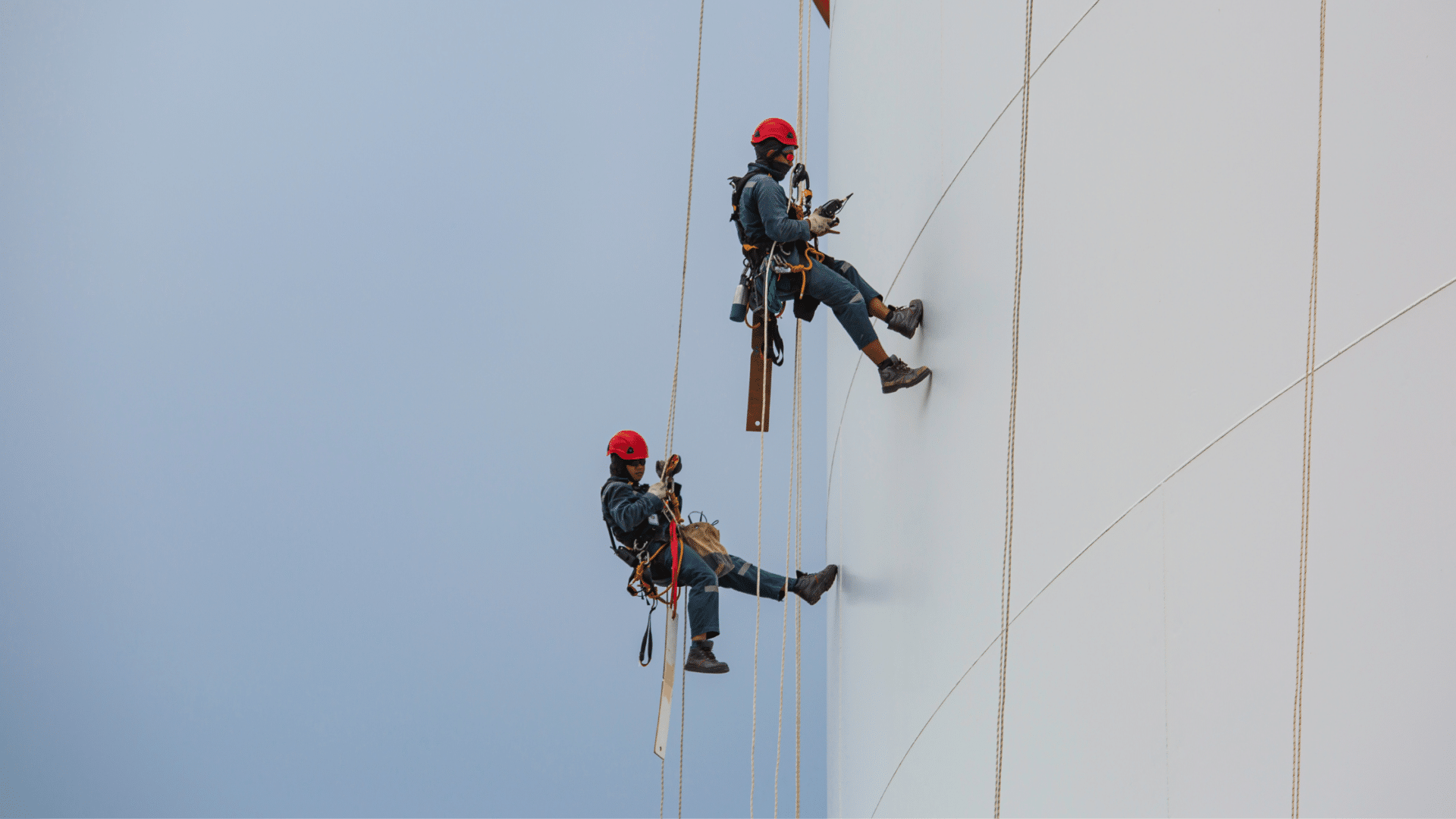

High-level cleaning requires specialized equipment and techniques. With over 25 years experience, Advance Cleaning Services have mastered processes and skills to clean high-level areas effectively. These techniques enable our teams to clean overhead surfaces thoroughly without compromising on safety or efficiency.

2. Rigorous Training and Safety Protocols

Safety is crucial in high-level cleaning, thus we ensure that all our staff are rigorously trained in using high-reach equipment and working at heights. Our teams undergo regular safety training and are equipped with personal protective equipment (PPE) to prevent accidents. This focus on safety ensures that cleaning operations are conducted without risk to personnel or the food and beverage facility.

3. Comprehensive Inspection and Cleaning Schedules

ACS designs customized cleaning schedules for each facility we service. These schedules include inspections at regular intervals and cleaning of high-level areas to prevent dust buildup and pest infestations. By adhering to a strict schedule, we ensure that high-level cleaning is not an afterthought but an integral part of your food and beverage facility’s overall hygiene plan.

4. Integration with Overall Cleaning and Maintenance Programs

High-level cleaning at ACS is integrated with the facility’s overall cleaning and maintenance programs. This holistic approach ensures that all areas, from the floor to the ceiling, are maintained to the highest standards. Regular communication and collaboration with the facility’s maintenance and quality control teams ensure that high-level cleaning activities do not disrupt production schedules.

The Benefits of High-Level Cleaning

Implementing high-level cleaning provides numerous benefits to food and beverage manufacturing facilities:

Enhanced food safety

By eliminating potential contamination sources above the typical cleaning range, high-level cleaning significantly enhances food safety. This proactive approach reduces the risk of contamination and ensures that products meet stringent safety standards.

Compliance with regulatory standards

High-level cleaning ensures compliance with food safety regulations. ACS’s meticulous documentation and inspection processes provide verifiable proof of compliance, which is crucial during audits and inspections.

Extended equipment lifespan

Keeping high-level areas clean prevents dust and debris from settling on sensitive equipment, thus extending its lifespan. Regular cleaning reduces wear and tear, leading to fewer repairs and replacements.

Advanced Cleaning Services has built a reputation for excellence in professional cleaning by consistently delivering superior results. Our clients include some of the largest food manufacturing companies and we are proud to safeguard their brands through our comprehensive service offering. Contact us for more information on how we can assist your facility with its cleaning requirements.